Dry Bulk Storage Tank And Dome

08/06/2020 · 8:07am

Tank Connection provided this Bolted RTP and aluminum geodesic dome dry stockpile containment solution for a fluorspar mining operation in Canada.

Looking for more technical information?

ASK THE EXPERT Get The DetailsTank Connection is a leading supplier of cement st...

Learn More

Tank Connection is an industry leader in the stora...

Learn More

Tank Connection is one of the largest suppliers of...

Learn More

In power utility service, we provide the highest q...

Learn More

Our precision RTP (rolled, tapered panel) construc...

Learn More

Does your project require an agricultural process ...

Learn More

Tank Connection can assist with your storage tank ...

Learn More

Tank Connection shop-welded storage tanks are the ...

Learn More

Food storage is offered in shop welded, field-weld...

Learn More

Biopower is the use of biomass to generate electri...

Learn More

Tank Connection is the industry leader in dry bulk storage tanks. Tank Connection is the only storage tank supplier worldwide that offers all four major types of steel storage tanks. Tank Connection offers bolted RTP (rolled, tapered panel) storage tanks, field-welded storage tanks, shop-weld storage tanks, and hybrid storage tank construction. For a complete integrated storage tank system including all auxiliary equipment, Tank Connection project management services are the best in the industry. Not only are we recognized as the experts in dry bulk storage applications, but we specialize in all types of material flow discharge systems including functional mass flow, funnel flow, expanded flow, active/vibratory discharge and numerous configurations of fluidized hopper designs. In dry bulk storage tank applications, we can minimize and eliminate the problems of yesterday by prescribing the right storage tank system to interface with an existing or new material handling system. We provide total turnkey responsibility supplied by one company, Tank Connection!

With cement storage tank systems, we can provide you with the most cost efficient approach for a complete storage and truck load out facility. In coal storage, we provide functional mass flow or expanded flow discharge systems to prevent material bridging inside the silo and provide reliable material flow. In sand storage, we provide complete rail unload, storage and truck load-out facilities. In lime storage, we lead the industry in turnkey storage systems for limestone, lime, hydrated lime, pebble lime and quicklime applications. The list continues – just know that Tank Connection wishes to partner with you to provide the best dry bulk storage tank or system to meet the needs of your project.

When your project demands the best technology for storing dry bulk materials, connect with the company that can provide you with answers not rhetoric, Tank Connection!

Tank Connection provided this Bolted RTP and aluminum geodesic dome dry stockpile containment solution for a fluorspar mining operation in Canada.

Lime storage silos on elevated structural steel. Each silo includes a deck platform that together create a superstructure platform at the top of the silos. The twelve lime storage silos each have a capacity of 119,700 cubic feet (3,389.5 cubic meters)

Accenting the horizon of western Texas, this impressive array of bolted RTP (Rolled, Tapered Panel) silos serve as frac sand storage.

This beautifully constructed bolted RTP (Rolled, Tapered Panel) silo, built in partnership with McMahon Services Australia and Ammermann Partners, stores 3,000 This beautifully constructed bolted RTP (Rolled, Tapered Panel) silo, built in partnership with McMahon Services Australia, stores 3,000 metric tons of cement and serves the local Australian market.

Tank Connection’s bolted RTP (Rolled, Tapered, Panel) silos feature reliable product flow, and remarkable coating toughness. Bolted RTP designs provide the freedom of diverse configuration and accessory options.

These bolted RTP limestone storage silos serve as kiln feed storage for cement production.

This large bolted RTP silo stores dry, free-flowing cement. It sits upon an enclosed structural steel and cement elevated platform, and can withstand hurricane force winds.

Tank Connection's Bolted RTP silo serves as the centerpiece of this large cement terminal facility in Melbourne, Australia.

Tank Connection is the leading bolted tank manufacturer for factory coated bolted storage tanks and aluminum bulk storage covers for dry bulk storage applications. Tank Connection dry bulk storage solutions include superior engineered tank, hopper and aluminum cover designs, unmatched coating technology, and golden rule of customer service.

In dry bulk storage, we are the industry leader for large bulk storage facilities in North America.

Tank Connection offers all types of “functional mass flow” storage systems available for the storage of dry bulk materials. Based on a sample of your material tested on a Jenike Shear Tester, Tank Connection can design a “functional mass flow” storage system that will provide consistent, reliable performance in the field. Tank Connection backs it with a performance guarantee.

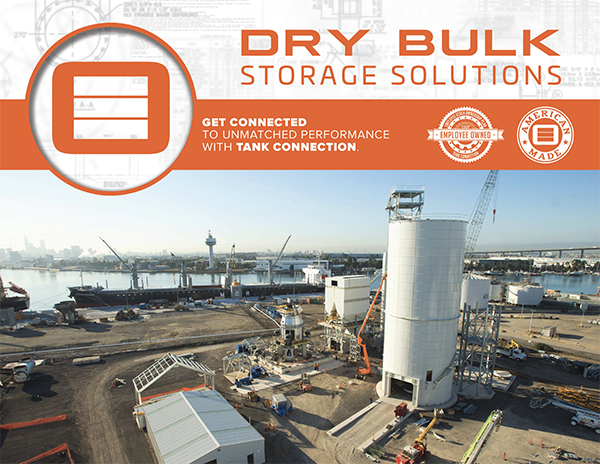

Tank Connection construction crews installed this Barge-to-Truck transloading terminal with a 127’ tall by 41.5’ diameter RTP bolted Cement Storage Silo to store and transfer cement from ocean barges. Tank Connection also designed, supplied and installed the pneumatic conveying piping and the unloading system.

Tank Connection construction crews battled through the mighty trade winds of Aruba and successfully installed a Barge-to-Truck transloading terminal with a 133’ tall by 42’ diameter Tank Connection RTP bolted Cement Storage Silo at the Barcadera Port in Aruba.

This state of the art facility consists of (6) 2000 MT silos with a total operating storage capacity of 8,000 cubic meters. Unique to this facility is the support for both rail and truck material receiving.

This power facility required a pebble lime silo, recycle ash silo and two welded well water tanks for their scrubber and baghouse project. Our pebble lime silo included multiple interior equipment levels, stairs, platforms, entryways, and extensive shell penetrations for customer piping and equipment.