The APEX Domes Advantage | Kansas Water Treatment Facility

04/04/2019 · 9:55am

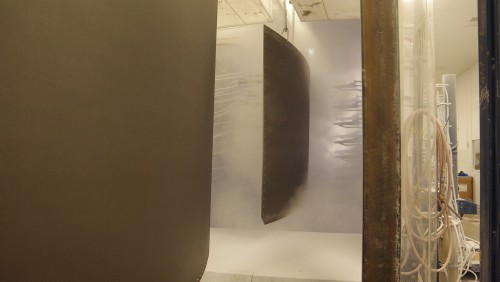

Water treatment facility upgrade in Southeast Kansas featuring six customized APEX Domes aluminum covers.

Looking for more technical information?

ASK THE EXPERT Get The DetailsAt Tank Connection, we rightfully claim the #1 bol...

Learn More

Tank Connection liquid tank designs deal with the ...

Learn More

In today’s wastewater market, Tank Connection’...

Learn More

Tank Connection designs, manufactures and installs...

Learn More

In anaerobic digester applications, Tank Connectio...

Learn More

At Tank Connection we offer a variety of storage t...

Learn More

Tank Connection is a leading manufacturer of field...

Learn More

In liquid storage tanks systems, Tank Connection manufactures the #1 bolted storage tank available worldwide. Tank Connection's LIQ Fusion 8000 FBE™ coating system is a stronger system than porcelain enamel (glass) and is superior to all field applied storage tank coating systems.

At Tank Connection, we rightfully claim the #1 steel water tank design and liquid coating system available.

Does your project specify a single steel water storage tank or an integrated municipal water storage tank system? Tank Connection will work with you to develop the best solution for your liquid storage needs. From the quote stage through order process, drawing approval, material fabrication and field installation, Tank Connection will provide streamlined processing and Golden Rule customer service.

Water treatment facility upgrade in Southeast Kansas featuring six customized APEX Domes aluminum covers.

Stainless steel bolted RTP + aluminum dome storage for food processing applications

This Bolted RTP potable water storage tank blends into the brilliant green New Zealand landscape. It features a special coated aluminum geodesic dome provided by APEX Domes.

Tank Connection leads the industry in liquid contain solutions, with superior coating technology, versatile design, expert engineering, and industry experience.

Tank Connection was chosen for this massive water storage facility in Singapore. The project features 13 water storage tanks for reverse osmosis flush/feed applications. Five of these tanks are 135.39 feet (41.27 m) in diameter by 46.08 feet (14.05 m) in height, with a capacity of 4,755,096.9 gal (18,000 cubic meters) each, and feature aluminum geodesic dome covers.

Tank Connection provides the best performance coating system available for water storage.

When specifying liquid tanks for municipal, industrial, and agricultural projects, it is important to not only understand the design specifics, but also the coating requirements.

Biothane was selected for construction of a wastewater facility in support of a distillery in St. Croix. The large digesters utilize a base setting ring (BSR) design and are fitted with a floating membrane cover. The effluent buffer tank utilizes a BSR and is designed to accept a double “gas holder” membrane cover. Equalization tank utilizes BSR design and is open top. Post aeration tank utilizes BSR design and steel pressure deck design supplied by Tank Connection.

Tank Connection was chosen for this bolted RTP (rolled, tapered panel) construction tank that has a capacity of over 170,000 gallons for fire protection water usage in Texas.

This is the first tank that Tank Connection utilized this style of rafter ring. The rafter ring was designed to set within 1 inch of the grating level per customer request. In addition, the nozzles were designed to protrude through the platforms to give the customer access to bolt the piping to the flanges. This was a special request by our customer, and they were very happy with the result.

Tank Connection was selected to design, manufacture and install a turnkey package for over 4 million gallons of frac water storage. The customer owns and operates their own oil and gas wells and contacted Tank Connection to assist in finding the most economical storage solution for their frac sand operation.