Tank Connection’s RTP Bolted Liquid Storage Tanks Outperforms Concrete Tank Construction!

SOME SIMPLE FACTS TO CONSIDER - RTP STEEL vs. CONCRETE:

- Today’s bolted RTP steel tank technology is #1 bolted tank design selected worldwide. It does not leak or develop leaks.

- Concrete water storage tanks are problematic…..they crack…..and they leak. To uninformed buyers, it may surprise you to know that concrete tanks are designed to allow for an acceptable amount of leakage. So we ask the question . . . how much leakage is acceptable to your client?

- The best application for concrete construction in water and wastewater storage applications include:

- The tank foundation

- Storage applications requiring tank construction below ground level

- Elevated water tank support pedestals

- Steel tanks are rapidly replacing concrete digester tanks across Europe. Concrete storage tanks storing water and wastewater do not stand up to the test of time.

- Concrete dome covers merit no value in today’s advanced storage technology. If a storage tank component does not merit value in its application, you can typically assume that it may be a liability. Concrete covers are a major weak link in liquid storage applications.

RTP STEEL OUTPERFORMS CONCRETE (continued)

- The best dome cover in the marketplace for water and wastewater applications are aluminum geodesic domes. Across the next few years, aluminum geodesic domes will be the specified “product of choice” for all types of liquid storage containment tanks including concrete, bolted steel and field-welded construction.

- The performance of aluminum geodesic dome construction has proven to be phenomenal compared to concrete construction.

- Bolted RTP field construction allows control of all field construction processes in good or bad weather.

- Concrete construction in the field is subject to numerous uncontrolled factors from outside influences. From mixture specifications to joint connections, concrete construction in the field is subject to a high level of varying quality control even with stringent quality control procedures in place.

- Wire-wound prestressed concrete with a steel diaphragm embedded in the tank wall is the premier concrete storage tank. A steel diaphragm is utilized for a watertight barrier and to assure a leak proof tank wall. (In other words, a very thin steel tank is utilized inside the concrete to keep it from leaking).

- Bolted RTP construction by Tank Connection utilizes a heavy steel tank for a leak proof tank wall………except without the burden of concrete.

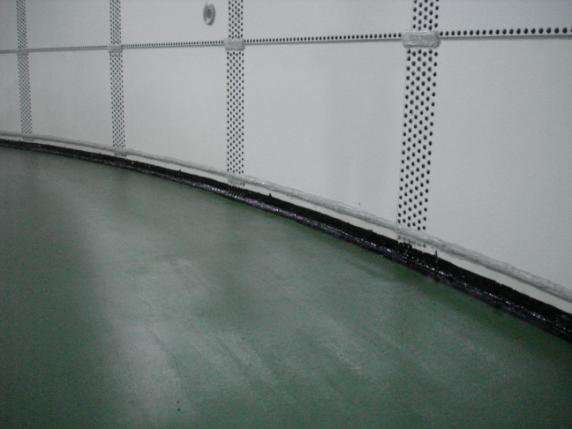

- RTP (rolled, tapered panel) Bolted Construction

- LIQ Fusion 7000 FBE™

- Aluminum Geodesic Dome

- Limit the concrete to the foundation

- Base setting ring utilized

RTP STEEL OUTPERFORMS CONCRETE (continued)

- Bolted steel tanks are easily repaired if damaged in the field. Field repairs on bolted tanks make the tank as good as new.

- Concrete tanks are never easily repaired, but rather only patched and sealed. Crack repairs on concrete tanks are considered patches only and are never ending.

- Concrete tank construction promotes some of the most architectural and aesthetic tank designs in municipal applications. Tank Connection promotes the same aesthetic tank features in steel tank construction.

- Concrete tank construction will cost over twice as much as steel tank construction.

- The service life of bolted RTP construction coated with LIQ Fusion 7000 FBE™ by Tank Connection will exceed or equate concrete tank construction.

- The life cycle cost savings of bolted steel RTP construction over concrete is significant.

To summarize, bolted steel tanks utilizing precision RTP (rolled, tapered panel) technology outperforms concrete (i.e. wire, strand-wound, circular, prestressed) tank construction.

In water and wastewater storage applications, limit the concrete to the foundation and install a steel tank for performance. The cost savings will be significant and the tank performance will be unmatched.

Specify Wisely!

About Tank Connection:

Tank Connection is recognized as a global leader in storage containment

applications. Tank Connection is the only tank supplier worldwide that designs, manufactures and installs all four

types of steel storage tanks including bolted RTP, field-weld, shop-weld and hybrid tank designs for

industrial liquid storage. Their precision RTP (rolled, tapered panel) construction is the #1 bolted tank

design selected worldwide. The best features of bolted and field-weld tank construction have been

combined together in the RTP design. It remains unmatched in the industry in all category ratings.

Tank Connection also provides complete turnkey field installation service, utilizing a tec-synchronized, hydraulic screw jack process, which allows field crews to install liquid storage tanks at grade level. LIQ Fusion FBE™ coating system is NSF 61-approved and is unmatched in performance compared to all bolted tank coatings. LIQ Fusion 7000 FBE™ is a stronger system than "porcelain enamel/glass" for industrial liquid storage applications.

On your next project, “GET CONNECTED” with the industry leader and unmatched performance of the Tank Connection Affiliate Group!