Dry Bulk Storage Tanks

Tank Connection can specify the most appropriate dry-bulk storage tank method for your tank application needs.

Learn MoreRoutinely, we are asked what factors contributed to the company’s exponential growth over the last decade. From day one we set our charter that defined our mission, vision and core values. To condense our view, we wanted Tank Connection to focus on listening to clients and providing them with factual information on different types of storage containment options. Our approach to service clients is based on the development of a broad product line of superior storage tank products, designs and field construction services. Initially, our product line included bolted, shop-welded and field-welded tank construction. As our company developed, we added hybrid tank designs, aluminum geodesic domes, elevated water tank designs, composite pedestals and other types of containment covers. At Tank Connection, we simply focused our efforts on developing high performance, above ground storage tank systems.

If you have questions about dry bulk or liquid storage tanks, contact Tank Connection today.

Tank Connection can specify the most appropriate dry-bulk storage tank method for your tank application needs.

Learn MoreIn liquid storage tanks systems, Tank Connection manufactures the #1 bolted storage tank available worldwide.

Learn MoreTank Connection designs, manufactures, and constructs the best aluminum geodesic domes in the industry.

Learn MoreWe remedy the storage problems of the past by prescribing the correct variables of hopper slope, outlet size, outlet configurations, materials of construction and surface finish, active flow-aid devices, passive flow-aid devices, internal and external coatings systems, applicable codes and the correct flow type required for reliable material flow. Our proprietary coating systems, DRY Fusion 5500 FBE™ and LIQ Fusion 8000 FBE™ exceed the competition in durability, performance and cost-effectiveness.

Tank Connection is a leading manufacturer of specialty steel fabrication in North America.

Learn MoreTank Connection is the leading manufacturer of structural support steel for all storage tank applications.

Learn MoreTank Connection strives to provide the best customer experience available.

Learn MoreOur products and services are recognized in the industry for setting a new benchmark of quality and field performance. Tank Connection is also the only tank manufacturer worldwide that designs, fabricates and installs all types of steel storage systems including bolted RTP (rolled, tapered panel), field-weld, shop-weld and hybrid tank construction.

With sales outlets worldwide, Tank Connection is the ultimate SINGLE SOURCE storage tank manufacturer for all types of storage containment systems.

Contact UsOur reputation is built on success and we recognize our clients for that success. We are the solution people and we build project success. Give us a call on your next project and let us assist you in specifying practical, cost efficient, storage tanks that work.

Tank Connection's growing line of premier aluminum tank covers take product protection to the next level. Tank Connection Covers feature enhanced design and manufacturing methods that provide increased flexibility and strength.

Tank Connection provided this Bolted RTP and aluminum geodesic dome dry stockpile containment solution for a fluorspar mining operation in Canada.

Do you have custom fabrication and/or custom coating requirements for your existing products and are looking for a new source? Are you getting ready to launch a new product and are unsure where to source your specialty fabrication and coating needs? Let Tank Connection Help. Tank Connection is ready to leverage their experience in manufacturing a wide range of industrial storage products to fulfill your custom fabrication and coating needs.

Lime storage silos on elevated structural steel. Each silo includes a deck platform that together create a superstructure platform at the top of the silos. The twelve lime storage silos each have a capacity of 119,700 cubic feet (3,389.5 cubic meters)

Water treatment facility upgrade in Southeast Kansas featuring six customized APEX Domes aluminum covers.

Accenting the horizon of western Texas, this impressive array of bolted RTP (Rolled, Tapered Panel) silos serve as frac sand storage.

This beautifully constructed bolted RTP (Rolled, Tapered Panel) silo, built in partnership with McMahon Services Australia and Ammermann Partners, stores 3,000 This beautifully constructed bolted RTP (Rolled, Tapered Panel) silo, built in partnership with McMahon Services Australia, stores 3,000 metric tons of cement and serves the local Australian market.

Tank Connection’s bolted RTP (Rolled, Tapered, Panel) silos feature reliable product flow, and remarkable coating toughness. Bolted RTP designs provide the freedom of diverse configuration and accessory options.

Stainless steel bolted RTP + aluminum dome storage for food processing applications

These bolted RTP limestone storage silos serve as kiln feed storage for cement production.

This Bolted RTP potable water storage tank blends into the brilliant green New Zealand landscape. It features a special coated aluminum geodesic dome provided by APEX Domes.

Tank Connection leads the industry in liquid contain solutions, with superior coating technology, versatile design, expert engineering, and industry experience.

This large bolted RTP silo stores dry, free-flowing cement. It sits upon an enclosed structural steel and cement elevated platform, and can withstand hurricane force winds.

Tank Connection's Bolted RTP silo serves as the centerpiece of this large cement terminal facility in Melbourne, Australia.

Tank Connection was chosen for this massive water storage facility in Singapore. The project features 13 water storage tanks for reverse osmosis flush/feed applications. Five of these tanks are 135.39 feet (41.27 m) in diameter by 46.08 feet (14.05 m) in height, with a capacity of 4,755,096.9 gal (18,000 cubic meters) each, and feature aluminum geodesic dome covers.

Tank Connection is the leading bolted tank manufacturer for factory coated bolted storage tanks and aluminum bulk storage covers for dry bulk storage applications. Tank Connection dry bulk storage solutions include superior engineered tank, hopper and aluminum cover designs, unmatched coating technology, and golden rule of customer service.

Tank Connection provides the best performance coating system available for water storage.

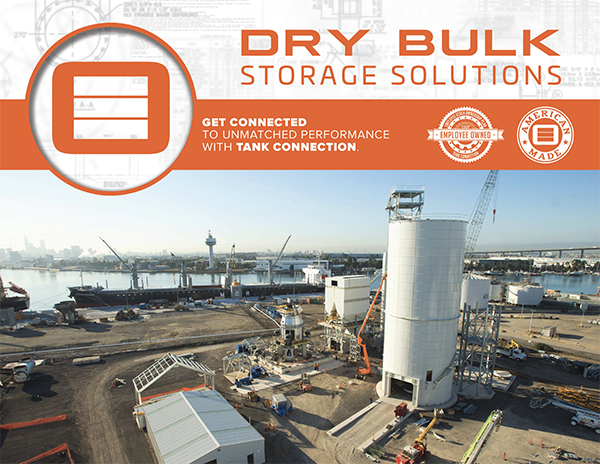

Tank Connection construction crews installed this Barge-to-Truck transloading terminal with a 127’ tall by 41.5’ diameter RTP bolted Cement Storage Silo to store and transfer cement from ocean barges. Tank Connection also designed, supplied and installed the pneumatic conveying piping and the unloading system.

Biothane was selected for construction of a wastewater facility in support of a distillery in St. Croix. The large digesters utilize a base setting ring (BSR) design and are fitted with a floating membrane cover. The effluent buffer tank utilizes a BSR and is designed to accept a double “gas holder” membrane cover. Equalization tank utilizes BSR design and is open top. Post aeration tank utilizes BSR design and steel pressure deck design supplied by Tank Connection.

Tank Connection was chosen for this bolted RTP (rolled, tapered panel) construction tank that has a capacity of over 170,000 gallons for fire protection water usage in Texas.

This is the first tank that Tank Connection utilized this style of rafter ring. The rafter ring was designed to set within 1 inch of the grating level per customer request. In addition, the nozzles were designed to protrude through the platforms to give the customer access to bolt the piping to the flanges. This was a special request by our customer, and they were very happy with the result.

Tank Connection was selected to design, manufacture and install a turnkey package for over 4 million gallons of frac water storage. The customer owns and operates their own oil and gas wells and contacted Tank Connection to assist in finding the most economical storage solution for their frac sand operation.

This state of the art facility consists of (6) 2000 MT silos with a total operating storage capacity of 8,000 cubic meters. Unique to this facility is the support for both rail and truck material receiving.

This power facility required a pebble lime silo, recycle ash silo and two welded well water tanks for their scrubber and baghouse project. Our pebble lime silo included multiple interior equipment levels, stairs, platforms, entryways, and extensive shell penetrations for customer piping and equipment.