In cement and aggregate storage, Tank Connection leads the industry in storage and load out facilities. Our precision bolted RTP construction is the #1 bolted tank design selected for cement storage.

In cement and aggregate storage, Tank Connection leads the industry in storage and load out facilities. Our precision bolted RTP construction is the #1 bolted tank design selected for cement storage.

Tank Connection’s proprietary DRY Fusion 5500 FBETM and EXT Fusion SDPTM coatings are unmatched in the industry in all performance standards, including low maintenance and cost efficiency.

Reliable and fast truck fill times, all with fully integrated controls and database inventory management.

Tank Connection designed, supplied and installed the 750’ of underground pneumatic conveying pipe that stretches from the barge offload point in the Barcadera port into the cement silo.

Application: Store and transfer cement from ocean barges

Storage Type: Precision Bolted RTP Design

Quantity: 1

Diameter: 41.59 ft (12.7 m)

Height: 127.019 ft (38.7 m)

Volume: 4444 tons (4031 m3)

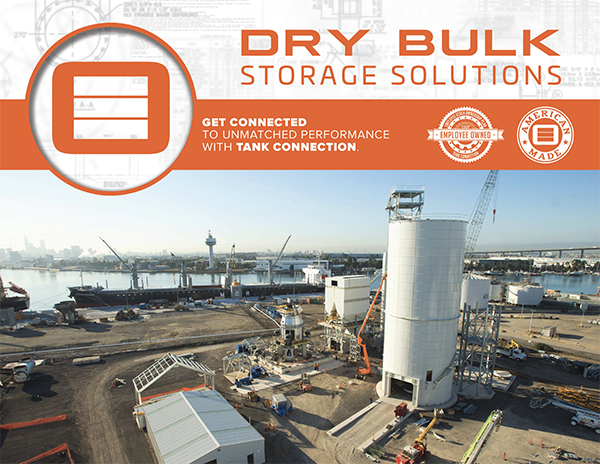

Tank Connection construction crews installed a Barge-to-Truck transloading terminal with a 127’ tall by 41.5’ diameter RTP (rolled, tapered panel) bolted Cement Storage Silo at the Barcadera Port in Aruba. The facility was designed to store and transfer cement from oceanic barges. Prior to the installation of this facility, cement was delivered to the island in large bags, prone to product contamination. Now, 750’ of underground pneumatic conveying pipe stretches from the barge offload point in the Barcadera port into the cement silo.

Tank Connection’s client, ATCO Concrete Products, produces ready mix cement and multi colored specialty blocks and pavers for the construction industry. Their materials are used to build many of the luxurious high rise hotels, parks and beach front shopping areas that are a staple of Aruba’s tourism industry. This terminal will serve ATCO’s plant with cement to support its computerized, state of the art block plant.

Tank Connection designed, supplied and installed the pneumatic conveying piping and the unloading system. The silo cement unloading system fluidized the cement to provide reliable and fast truck fill times, all with full integrated controls and database inventory management. The system is designed to provide accurate product quantities to the plant operations managers as well as directly to the cement suppliers so that daily operations and monthly barge deliveries can be integrated into a seamless, uninterrupted supply chain.

Application Store and transfer cement from ocean barges

Project Barge-To-Truck Cement Terminal - Bacadera Port, Aruba

View more info on our

Cement Storage Tanks View All

Tank Connection is the leading bolted tank manufacturer for factory coated bolted storage tanks and aluminum bulk storage covers for dry bulk storage applications. Tank Connection dry bulk storage solutions include superior engineered tank, hopper and aluminum cover designs, unmatched coating technology, and golden rule of customer service.