Dry Bulk Storage Tank And Dome

Date: 08.06.2020

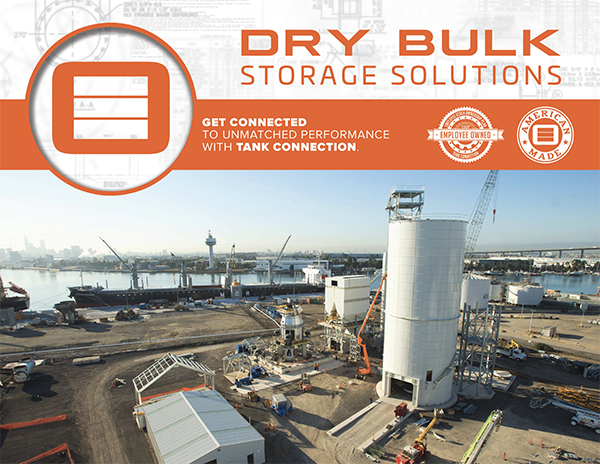

When asked to provide a dry stockpile containment solution for a mining operation in Canada, Tank Connection sales and engineering teams developed an innovative solution by combining their bolted RTP (Rolled, Tapered Panel) sidewalls along with their aluminum geodesic dome roof. The client had previously relied on a fabric building for their in-process fluorspar ore storage application. However, due to the temperamental weather and strong winds of the North Atlantic coast, the fabric building was destroyed within the first year of use. Tank Connection worked with the client exploring various options. The Tank Connection team had to consider in the product design: the extreme environment; a fixed, cantilever stacking conveyor; and a drive through sidewall opening for material access. The end result was to utilize Tank Connection’s bolted RTP tank design that would support an aluminum geodesic dome.

Tank Connection’s bulk storage product serves the client’s facility by providing a permanent, all-weather enclosure for the fluorspar ore that is reclaimed by a front-end loader as the process requires. Fluorspar is considered a strategic mineral by many countries and downstream is utilized in many different industries and products: batteries, refrigerant, and computer equipment to name a few.

PRODUCT PERFORMANCE

Approaching the concept with bolted steel panel walls, rather than field-welded or concrete structures, provided many advantages to the client. The application of bolted RTP construction offered flexibility and the option for the entire project to be supplied in full by one provider. Tank Connection’s factory-applied coating technology has a proven track record of outperforming all other coatings in the industry. The modular tank design allows for quick and easy installation by the customer. The capabilities of Tank Connection’s bolted RTP results in a robust, reliable, and cost efficient bulk storage solution that will stand the test of time and the elements. Bolted RTP leverages optimal plate design thicknesses, and is recognized as a replacement in many applications where traditionally field welded and concrete tank construction would have been used.

The geodesic aluminum dome covering the bolted RTP structure is manufactured by APEX Domes. This Tank Connection product line features specialized component design to increase strength and flexibility while being designed to Aluminum Design Manual (ADM) 2005/2010 & 2015. APEX Domes are routinely used in Tank Connection’s liquid product line for new construction or retrofit applications. For bulk storage containment, APEX Domes are custom designed for dry bulk storage solutions and the strong clear span design minimizes foundation loads and maximizes storage capacity.